Explore What’s Possible with Solid Lab

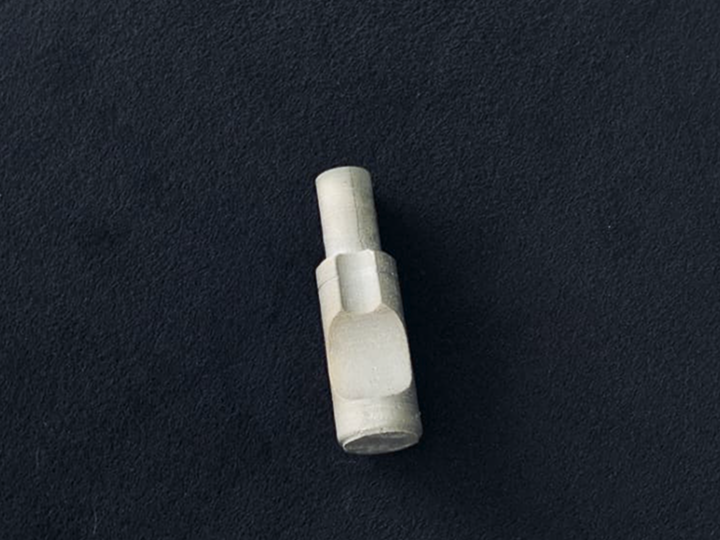

A discontinued camlock stud from legacy machinery was successfully reverse-engineered and printed in stainless steel. The functional replacement part was completed within 7 days.

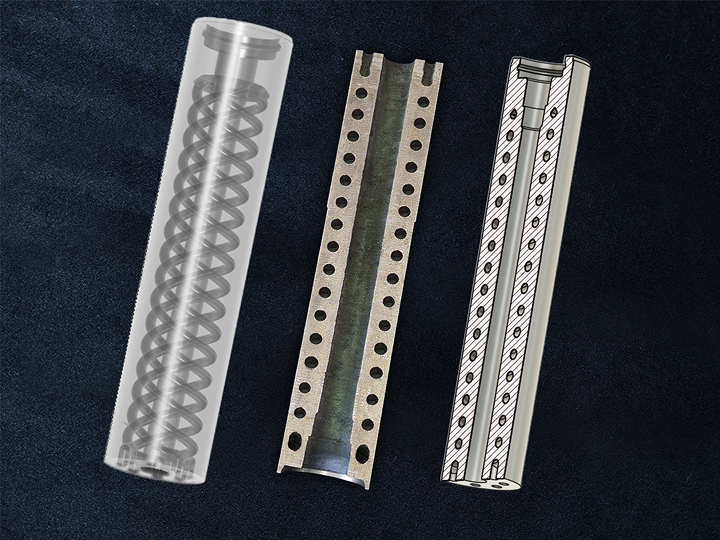

Engineering Optimisation Parts

A mould insert was designed with conformal cooling channels that follow the part’s geometry, enabling more efficient heat dissipation.

Rapid Part Production

A custom bracket was designed, printed, and sintered in just 4 working days. The process demonstrated significantly shorter lead time compared to conventional machining.

https://www.youtube.com/watch?v=PCn8XdbdQhY

Our AM technology is capable of producing a wide range of metals and composites, cost-effectively

Solid Lab wins THE Awards 2025 – Research Project of the Year: STEM

Solid Lab wins THE Awards 2025 – Research Project of the Year: STEM

We are excited to announce that Solid Lab, in collaboration with UTAR, has won the prestigious “Research Project of the Year: STEM”…

Solid Lab @ MRANTI Supercharger Showcase

Introduction of our SMX™ 3D Printing System to the Minister of Science, Technology & Innovation, YB Dato' Sri Dr. Adham…